BMW Group opened its first car manufacturing facility outside of Germany ever near Pretoria, South Africa, 50 years ago. Since then, the intrepid plant has delivered vehicles all over the world, including the United States. But, the plant is a far cry from what it once was. Alongside the breadth of BMW Group’s South African operations, the plant expands. It’s now home to a sales center for BMW, MINI, and Motorrad, a branch for Financial Services, a vehicle distribution center, and more.

There’s no question that Plant Rosslyn has been an indispensable and central component of BMW’s growth through the years. But, despite this being arguably one of the most important sites in BMW Group history, it’s often overlooked. People tend to favor the German plants – or perhaps Plant Spartanburg, home of the Sports Activity Vehicle. But Plant Rosslyn is very important – and here’s a little bit more about it.

Plant Rosslyn: the Core of BMW Group South Africa’s Operations

As mentioned, Plant Rosslyn now represents almost every aspect of BMW’s South Africa operations. It began in 1968 as a BMW assembly site for locally-based Praetor Monteerders. The local company sourced BMW engines and drivetrains fitted to Hans Glas sheet metal, shipped straight from Dingolfing. In 1973, BMW AG took over and established the site as Plant Rosslyn.

In the 1990s, the focus shifted to producing cars for export, and the first model for export was the 3 Series. The plant has produced various generations of the 3 Series, with nearly 1.2 million cars built. In 2018, the production of the BMW X3 began at the plant. In 2023, the plant has achieved significant production milestones, with expectations of hitting 400,000 units.

To date, 1.6 million vehicles have been exported to more than 40 countries from the plant. BMW claims they’ve invested R16.13 billion (around $874 million) into Plant Rosslyn since 1996. But the plant’s auspicious past is nothing compared to the bright horizons ahead of it. BMW is sinking another R4.2 billion in specialist training and sustainability strategies.

The factory follows strategic orientations of Lean, Green, and Digital, focusing on efficiency, sustainability, and technology. Therefore, the quality of BMW cars is consistent worldwide, including those from the Roslyn plant. Most cars produced (96%) are exported. Despite the high cost of shipping materials to South Africa and exporting the finished cars, BMW has found it economically advantageous to produce cars in Rosslyn. This is due in part to the free trade agreement between South Africa and Europe, which allows BMW to import cars into Europe more cheaply than it could from the United States. Additionally, South Africa offers a number of incentives to automakers, which helps to offset the higher costs of production.

The Rosslyn plant is now preparing for the next generation BMW X3 (G45) which will begin in mid-2024. The South African plant will be sole producer of the plug-in hybrid X3. No plans yet for the Neue Klasse production, but Dr. Niklas Fichtmüller, Director of BMW Group Plant Rosslyn, says the plant is on its way to future electrified models.

Contributing Significantly To The Local Economy and People

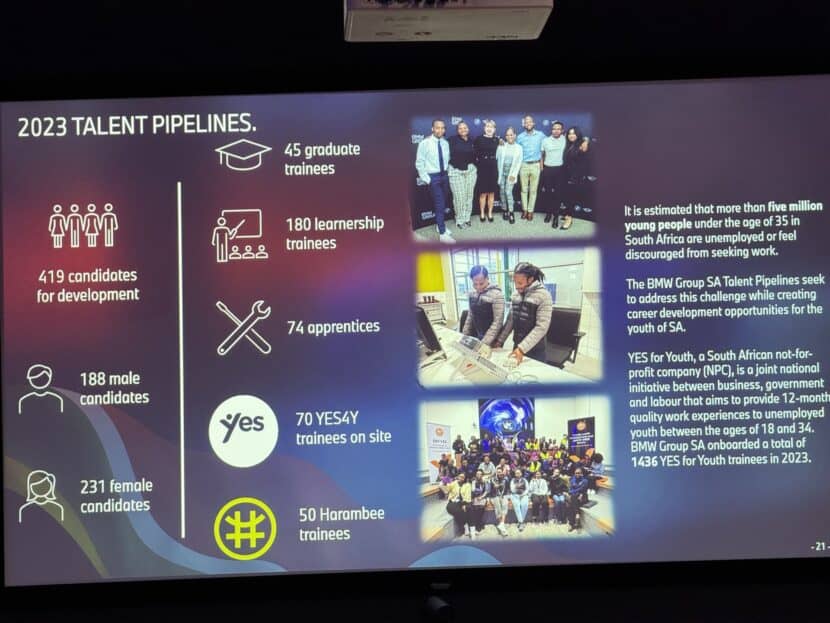

BMW Plant Rosslyn is a significant contributor to the South African economy, both directly and indirectly. The plant employs nearly 3,000 people and supports a supplier network of 14,500 jobs. Indirectly, over 50,000 jobs are created. Within the plant, 30 percent of the workforce are women, but the plant’s leadership acknowledges that there is more room for improvement in bridging that gap. The talent pipeline is already showing a 55-45 split female-to-male.

Building More Than Cars

BMW’s slogan for the Rosslyn plant is “Building more than cars.” This slogan reflects the plant’s commitment to making a positive contribution to South Africa beyond simply producing cars.

The plant has a number of programs in place to support the local community, including:

- Education and training: BMW offers a variety of education and training programs to its employees and to members of the local community. These programs help to develop the skills and knowledge that are needed to succeed in the workplace.

- Entrepreneurship development: BMW supports a number of entrepreneurship development programs in South Africa. These programs help to create new businesses and jobs.

- Social development: BMW supports a number of social development programs in South Africa, including programs that focus on education, healthcare, and community development.

Unemployment is South Africa is high: 40% percent overall and 60% for young people under the age of 35. Therefore, the BMW Group SA Talent Pipelines seek to address this challenge also in collaboration with government initiatives. YES for Youth, a South African not-for-profit company, is a joint venture between business, government and labor that aims to provide 12-month quality work experiences to unemployed youth between the ages of 18 and 34. BMW South Africa has onboarded over 1400 YES for Youth trainees in 2023.

Training Academy

The BMW Rosslyn Plant has wide array of programs tailored to different stages of an employee’s career journey. The Vocational Training Academy, established in 1978, provides foundational skills training, while the graduate program offers a structured two-year development path for recent graduates.

One of BMW Group South Africa’s key initiatives is the Digital Boost training program, which is offered to all employees, regardless of their role or department. The program covers a wide range of topics, including digital literacy, data analytics, and artificial intelligence. BMW Group South Africa is also investing in training programs specifically for electric vehicle production. For example, the company recently announced that 300 associates will receive training in electric vehicle production skills and competencies.

In addition to its training and development programs, BMW Group South Africa is also investing in its employees’ health and well-being. The company has a fully functional health management clinic on site, which provides a range of services, including general practice, dentistry, optometry, and pharmacy. BMW Group South Africa also offers a comprehensive medical aid scheme to its employees and their families.

At a broader level, across the entire South Africa BMW operations, the company’s development ecosystem extends from early childhood education to leadership development, encompassing a lifelong learning approach. BMW South Africa also actively partners with non-profit organizations like Harambee to connect youth with job opportunities.

Additionally, the company’s ZA BMW IT hub has successfully integrated young talent through various leadership initiatives in the IT space. (We will cover this in a separate article)

Diversity and Inclusion

BMW Group South Africa is also committed to diversity and inclusion. The company has a number of programs in place to support women and other underrepresented groups in the workplace. For example, the company has a Women in Leadership program, which targets middle-emerging leaders with demonstrated potential and performance. BMW Group South Africa is also a participant in the Rising Stars program, which nominates talent under the age of 40 who have the potential to grow.

Plant Rosslyn’s Sustainability Commitments

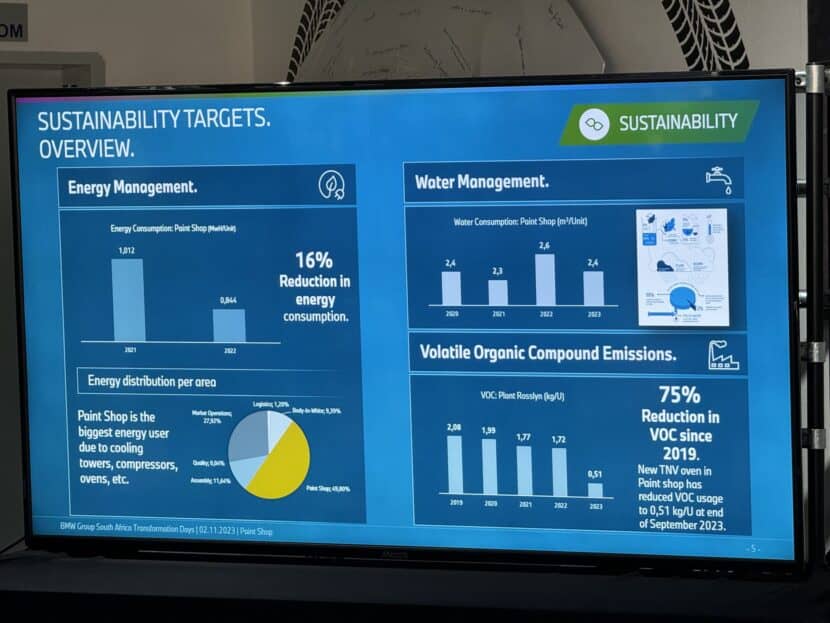

Though the plant is committed to a sustainable future, it has already taken steps toward minimizing its carbon footprint. Since 2018, energy use has been reduced by 14%, water usage cut by 38%, and landfill waste reduced by 100%. The plant even partners with eco-friendly building material supplier Envirolite. Envirolite makes bricks from waste polystyrene. So far, over 650 houses have been built from Plant Rosslyn’s reused polystyrene.

Here are some specific examples of BMW Plant Rosslyn’s sustainability initiatives:

- The plant has installed a 1.2 MW solar photovoltaic system on its roof, which generates enough electricity to power over 1,000 homes.

- The plant has also installed a rainwater harvesting system, which collects and stores rainwater for use in irrigation and other non-potable applications.

- The plant has reduced its waste output by over 90% through recycling and composting initiatives.

Another aspect BMW focuses on is supply chain sustainability. As a result, they spent 342 million Euros ($363 million) in 2022 alone direct purchasing from local businesses. Additional cash was spent on local services like cleaning crews, communication services (think: cable, etc), and food.

Collaboration With Other Plants, Like Spartanburg

According to Dr. Niklas Fichtmüller, the Rossly Plant collaborates with all the other factories in the network, including Spartanburg. Some key details about their collaboration include:

1. Talent Exchange: Employees from the Spartanburg plant in the U.S. are working at the South African site, and vice versa. This exchange of talent helps both plants gain exposure to different working environments, processes, and cultures, fostering a greater understanding of global operations.

2. Project Collaboration: The collaboration involves joint projects that are aimed at improving various aspects of production, including the preparation for the upcoming G45 BMW X3 vehicle.

3. Skills Transfer: The collaboration extends beyond just production preparation; it involves skills transfer and knowledge sharing. Employees from both plants bring their expertise and experiences to the table, contributing to a broader knowledge base that can benefit both sites.

4. Regular Meetings: Representatives from the South African, Spartanburg, and possibly other BMW plants come together at regular intervals, approximately every four weeks. These meetings serve as an opportunity to discuss the progress made, exchange information, and align strategies, ensuring a coordinated effort among different plants.

5. Adaptability and Flexibility: The collaboration also seems to highlight the adaptability and flexibility of BMW’s production strategy. The plants can respond to market demand for various vehicle types, including plug-in hybrid vehicles, by sharing resources, knowledge, and expertise to meet production requirements.

Plant Rosslyn: Marketplace of the Future?

South Africa was the first country to pilot direct sales from BMW Group. The New Retail Sales Model (NRSM) allows BMW to go from wholesaler to retailer, giving BMW, MINI, and Motorrad shoppers an unprecedented level of personalized service. Following a significant update in mid-2021, the system now offers features like Configurator Matching, bringing customers straight from the build-your-own tool to available inventory that matches their desired configuration.

Using data from this direct sales approach, BMW developed FSM, or Future Sales Model, which goes live in Europe for MINI in 2024 and BMW in 2026. FSM aims to increase customer contact points, expand services and benefits of retail channels, and enhance the retail experience. Dealerships aren’t going anywhere, though.

Plant Rosslyn: Local Pillar, Global Contributor

It’s clear that Plant Rosslyn is a huge part of the BMW Group’s global operation. But it’s more than that. It sets a precedent for companies that strive to make their production sites away from home a positive influence on their new locales. So, all while producing 61,609 vehicles and supporting 2,913 employees, Plant Rosslyn has also worked diligently to improve the day-to-day for countless residents and community members.

Of course, there is more work to be done, but BMW is committed to continue investing in South Africa through a wide range of initiatives.