It’s fair to say the competitiveness of motorsport has proven that humans have an innate need for speed. And this is perhaps more true in Formula 1 than any other sport, where victories can be decided by fractions of a millisecond.

Here, the combination of massive egos and equally massive sponsorship money has meant teams are constantly pushing each other with new and often revolutionary innovations that test the limits of the race rules.

In Part 1, we explored how this competition has led to advancements in material science, aerodynamics and suspension, which have filtered down to cars seen on the road today.

However, these are not the only areas in which improvements have been made. Powertrain and drivetrain technology, especially relating to engines, transmissions and hybridisation, are another crucial area of development that has seen certain advances translate into tangible benefits for road cars.

Powertrain technologies

Perhaps one of the most fundamental powertrain advances that can be attributed to Formula 1 is the development of a combination of features that set the template for contemporary internal-combustion engines.

This was established all the way back in 1912 by the Peugeot L76 Grand Prix (above), which featured a 7.6-litre inline four-cylinder engine and won both the French Grand Prix and the Indianapolis 500 race of that season.

More importantly, however, the L-76 was one of the first to demonstrate how a DOHC design (double overhead camshaft) with four valves per cylinder, together with compact hemispherical combustion chambers, could drastically improve engine performance, to the extent that many modern vehicles now follow the same basic layout.

-

Mercedes-AMG A45

Additionally, the L-76 also employed dry sump lubrication for improved engine cooling and to enable the car to have a lower centre of gravity – this system of lubrication continues to be used in countless high-performance cars today.

Turbocharged engines have long been a staple of modern road cars since the 1970s, but one of the more recent developments, as used especially by Mercedes-AMG and other brands, is the ‘hot vee’ engine design, whereby the turbochargers are placed within the ‘vee’ of the engine.

The objective of this design is to improve response and reduce turbo lag by reducing the distance that gases generated by the engine have to travel in order to spool up the turbochargers. Commonplace through models such as the Mercedes-AMG A45, this design was actually pioneered by the Ferrari 126C, launched originally for the 1981 Formula 1 season, which used a 1.5-litre V6 design producing at least 417kW of power.

Electrification has become increasingly important as a way for carmakers to meet stringent Euro 6 and upcoming Euro 7 emissions targets, and mild-hybrid systems are one approach to meet this challenge.

Many vehicles that feature mild-hybrid powertrains today adopt a combination of regenerative braking and a 48-volt battery that allows the vehicle to capture and convert kinetic energy from braking into electrical energy stored within the battery. In turn, the battery can be used to improve efficiency and performance by aiding the engine under certain driving conditions, such as when the car is accelerating, or directly powering ancillary systems such as the car’s air-conditioning.

The latest EQ Boost system in the new Mercedes C-Class is a prime example of this, providing an additional burst of power as necessary.

Mild-hybrid systems share fundamental similarities with the KERS (kinetic energy recovery system) that has been in use in Formula 1 since the 2009 season. While the F1 system also recovers kinetic energy from the car’s brakes and stores it in a battery or supercapacitor for later use, it has much more of a performance focus, with the latest KERS units being able to provide a temporary boost of 120kW when deployed by the driver.

-

Ferrari 640. Photo credit: Maurizio Cefariello

Transmissions

Decades ago Formula 1 cars made use of traditional manual gearboxes, However, teams sought to develop a gearbox that would be more compact, lighter and also allow for faster changes without the driver having to remove their hands from the wheel.

One of the more significant innovations in this space was the introduction of sequential manual gearboxes with an electronically controlled clutch (also known as a semi-automatic transmission). This transmission allowed the driver to change gears via steering-wheel mounted flappy paddles, and thereby eliminated the need to remove hands from the steering wheel to change gears.

John Barnard at Ferrari helped develop this system for the 1989 Formula 1 season, with the suitably equipped Ferrari 640 piloted by Nigel Mansell winning the Brazilian Grand Prix upon its debut. Within the next five years, almost all Formula 1 teams would decide to emulate this gearbox design, and the flappy paddle gearshift and sequential manual transmission remains in use to the present day.

-

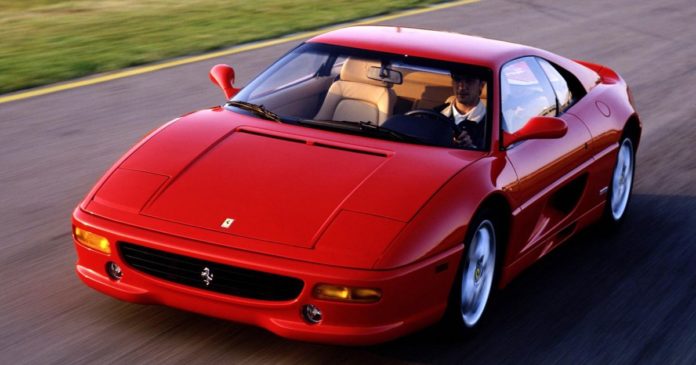

Ferrari F355 Berlinetta

The use of paddle shifters provided obvious ergonomic benefits, and these controls and the semi-automatic transmission were first adopted by a road car in 1997, available as an option on Ferrari’s F355 supercar, and aptly named the ‘F1’ transmission.

Other versions that used the same fundamental controls and principles included the less sophisticated Selespeed system, used on various Alfa Romeo and Fiat models such as the 156 and Punto respectively.

BMW also adopted a similar, but more sophisticated, system with its SMG (Sequential Manual Gearbox) transmission, as used on various M cars such as the E46 M3 and the E60 M5. In these cars, the driver was able to adjust shift points and shift speed with different preset options.

What road car most resembles an F1 race car today?

There are myriad vehicles available today that incorporate some of the technologies described above, with even entry-level models now featuring mild-hybrid technology, and paddle shifters (if not semi-automatic transmissions) widely used across the industry.

The Mercedes-AMG One is arguably the road car that most resembles an F1 car. The repeatedly delayed hypercar, which recently (belatedly) entered production, features the an F1-derived 1.6-litre V6 engine.

The engine has been tuned for road use with increased durability and a lower 11,000 RPM redline, and is mated with a KERS system that includes an MGU-K (Motor Generator Unit-Kinetic) and an MGU-H (Motor Generator Unit-Heat). An F1-style sequential manual transmission is also used.

Mercedes claims the AMG One engine is able to last up to 50,000 km before requiring factory refurbishment, and total system outputs are 782kW with a top speed in excess of 350 km/h.

MORE: Formula 1 technology in road cars: Part 1